Industrial PC

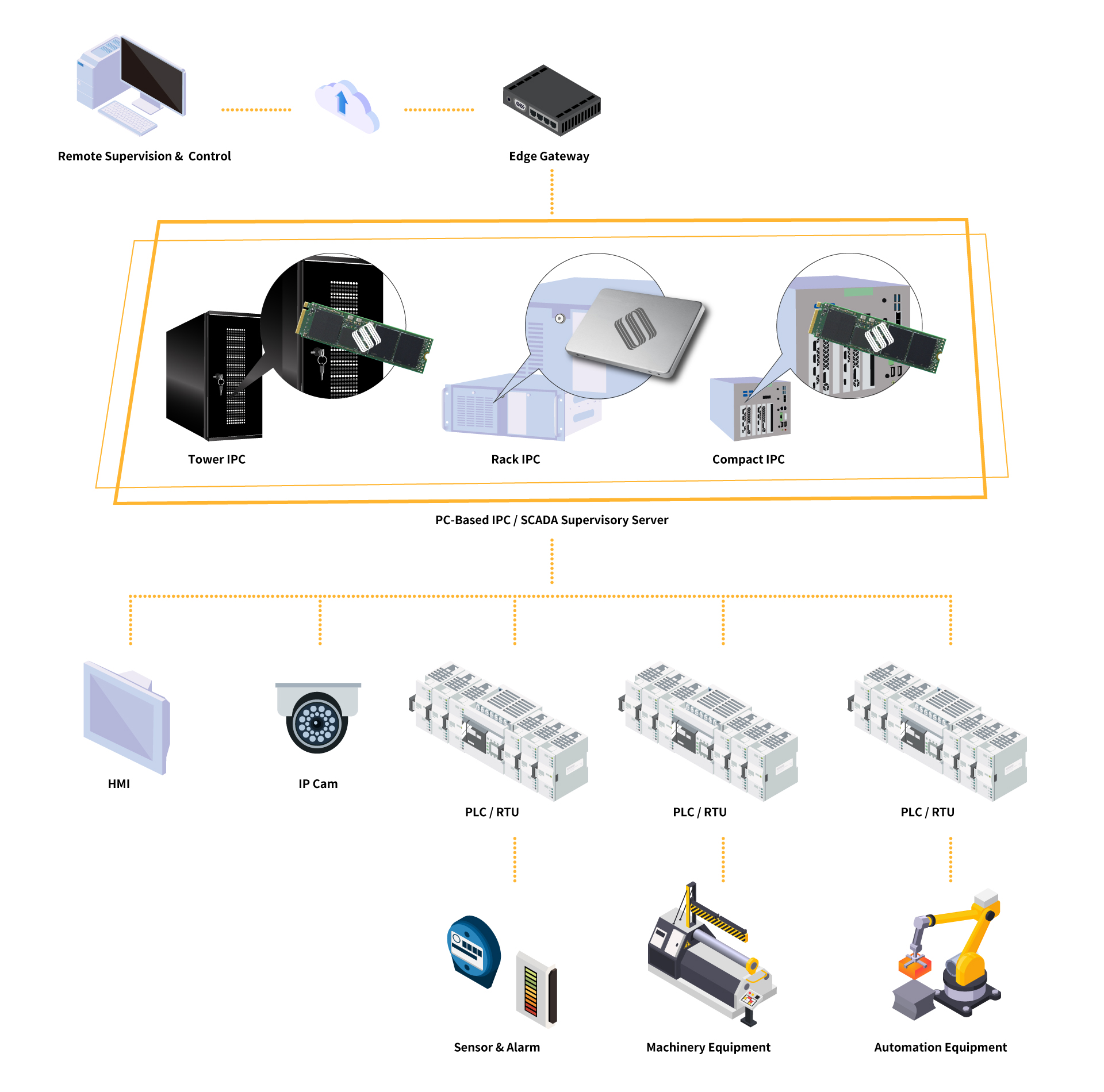

Industrial PCs were first utilized in factory automation manufacturing processes in controlling, monitoring, and testing equipment and machinery, but they were limited to Single Board Computers. With the standardization and low-pricing trend of PCs, the PC-Based industrial PCs have come to optimize the mainstream industrial automation applications.

The primary differentiation of industrial PCs from standard PCs is their industrial-grade motherboards supporting multiple expansion with ample PCle and PCI slots. Industrial-grade motherboards also provides several I/O ports (ie: Ethernet, VGA, DVI, HDMI, COM, RS-232/422/485, PS/2, USB ports, etc.) to acquire data transmission and to support all types of peripheral devices and accessories. The I/O ports are commonly designed for the front-end to speed up the applications of ATE (Automatic Test Equipment). The diverse expansion slots and I/O ports enable industrial PCs to have high expansion capabilities to connect with all industrial controllers, such as PLC (Programmable Logic Controller) and RTU (Remote Terminal Unit), or all types of expansion modules, to accommodate the complex industrial environment.

As there is a diverse range of industrial motherboards such as ATX, Micro ATX, Mini-ITX, ETX, etc., the slots of these motherboards vary, so there are various chassis. Furthermore, industrial PCs inherently need to upgrade their system architectures due to frequent changes in production flows, so the expandable motherboard and chassis are very critical. To facilitate convenient system maintenance and expansion, the chassis of industrial PCs features all kinds of opening mechanism such as single side-panel, L-Type, U-Type, and so forth, to address their possible installation locations. A more user-friendly design for industrial-PC applications requires minimize screw usage, or even adopts tool-less thumb screws which allows a maintenance person to carry out quick work.

In terms of exterior design, industrial PCs are comprised of Tower, Rack, and Compact. Regardless of the types of industrial PC, system protection is a fundamental and critical demand, which entails basic features such as dust-proof, waterproof, static-proof, shock-absorbing, vibration-proof, effective cooling, backup power supply, defect detection, and so forth. Advanced features such as wide operating temperature support, wide operating pressure support, EMP protection, and so forth is also available to satisfy all types of highly demanding industrial environment.

Industrial PC Working Flow Chart

Industrial automation requires ultra-reliable platforms to ensure uninterrupted and stable equipment and system operations, and consequently, data integrity. The industrial-grade Wide Temp SSDs of Solid State Storage Technology Corporation can meet the requirements of industrial automation applications, as they all pass the wide-operating-temperature tests before leaving the factory. The SSDs are tested to ensure their normal functioning within the temperature range of industrial application scenarios offered by customers without any component damage, data loss, read-write abnormality, and so forth. The industrial-grade SSDs produced by Solid State Storage Technology Corporation also pass the extreme voltage stress test, as well as comply with the Anti-Vibration standard of the US military standard, MIL-STD-810G, and Anti-Shock standard of the US military standard, MIL-STD-202G and MIL-STD-883.

Successful Case

ATA 2.5” SSDs produced by Solid State Storage Technology Corporation have been featured in various types of industrial PCs developed by the world's third largest industrial PC manufacturer.

SSD Model: CV8 / CVB Series SATA 2.5-inch SSD

SATA SSD

40GB / 80GB / 160GB / 256GB / 320GB / 640GB

NAND Flash: 3D pSLC(TLC)

Interface: SATA 3 (6Gb/s)

Sequential Read: UP to 550 MB/s

Sequential Write: UP to 510 MB/s

SATA SSD

120GB / 128GB / 256GB / 480GB / 512GB / 960GB / 1024GB / 2048GB

NAND Flash: 3D TLC NAND Flash

Interface: SATA 3 (6Gb/s)

Sequential Read: UP to 550 MB/s

Sequential Write: UP to 510 MB/s

NVMe™ SSD

80GB / 160GB / 320GB

NAND Flash: 3D pSLC(TLC)

Interface: PCIe® Gen4 x4

Sequential Read: UP to 3700 MB/s

Sequential Write: UP to 2600 MB/s

NVMe™ SSD

40GB / 80GB / 160GB / 320GB / 640GB /1280GB

NAND Flash: 3D TLC NAND Flash

Interface: PCIe® Gen3 x4

Sequential Read: 3,100 MB/s

Sequential Write: 1,500 MB/s

NVMe™ SSD

40GB / 80GB / 160GB / 320GB / 640GB /1280GB

NAND Flash: 3D TLC NAND Flash

Interface: PCIe® Gen3 x4

Sequential Read: 3,100 MB/s

Sequential Write: 1,500 MB/s

NVMe™ SSD

80GB / 160GB / 320GB

NAND Flash: 3D TLC NAND Flash

Interface: PCIe® Gen4 x4

Sequential Read: UP to 3,500 MB/s

Sequential Write: UP to 2,100 MB/s

NVMe™ SSD

128GB / 256GB / 512GB / 1024GB / 2048GB /4096GB

NAND Flash: 3D TLC NAND Flash

Interface: PCIe® Gen3 x4

Sequential Read: 3,100 MB/s

Sequential Write: 1,500 MB/s

NVMe™ SSD

128GB / 256GB / 512GB / 1024GB / 2048GB /4096GB

NAND Flash: 3D TLC NAND Flash

Interface: PCIe® Gen3 x4

Sequential Read: 3,100 MB/s

Sequential Write: 1,500 MB/s

NVMe™ SSD

256GB / 512GB / 1024GB / 2048GB

NAND Flash: 3D TLC NAND Flash

Interface: PCIe® Gen4 x4

Sequential Read: UP to 6,800 MB/s

Sequential Write: UP to 4,800 MB/s

NVMe™ SSD

240GB / 256GB /480GB/ 512GB / 960GB/ 1024GB

NAND Flash: 3D TLC NAND Flash

Interface: PCIe® Gen4 x4

Sequential Read: UP to 3,700 MB/s

Sequential Write: UP to 2,600 MB/s

NVMe™ SSD

256GB / 512GB / 1024GB

NAND Flash: 3D TLC NAND Flash

Interface: PCIe® Gen4 x4

Sequential Read: UP to 3,700 MB/s

Sequential Write: UP to 2,600 MB/s

NVMe™ SSD

128GB / 256GB / 512GB

NAND Flash: 3D TLC NAND Flash

Interface: PCIe® Gen3 x4

Sequential Read: UP to 2,000 MB/s

Sequential Write: UP to 1,100 MB/s

NVMe™ SSD

128GB / 256GB / 512GB/ 1024GB

NAND Flash: 3D TLC NAND Flash

Interface: PCIe® Gen3 x4

Sequential Read: UP to 2,000 MB/s

Sequential Write: UP to 1,100 MB/s

NVMe™ SSD

128GB / 256GB / 512GB

NAND Flash: 3D TLC NAND Flash

Interface: PCIe® Gen3 x4

Sequential Read: UP to 3,700 MB/s

Sequential Write: UP to 2,600 MB/s

SATA SSD

128GB / 256GB / 512GB / 1024GB

NAND Flash: 3D TLC NAND Flash

Interface: SATA 3 (6Gb/s)

Sequential Read: UP to 550 MB/s

Sequential Write: UP to 510 MB/s

SATA SSD

128GB / 256GB / 512GB

NAND Flash: 3D TLC NAND flash

Interface: SATA 3 (6Gb/s)

Sequential Read: UP to 550 MB/s

Sequential Write: UP to 450 MB/s

SATA SSD

128GB / 256GB / 512GB

NAND Flash: 3D TLC NAND Flash

Interface: SATA 3 (6Gb/s)

Sequential Read: UP to 550 MB/s

Sequential Write: UP to 450 MB/s

NVMe™ SSD

128GB / 256GB / 512GB

NAND Flash: 3D TLC NAND Flash

Interface: PCIe® Gen3 x4

Sequential Read: UP to 2,000 MB/s

Sequential Write: UP to 1,100 MB/s

SATA

128GB / 256GB / 512GB / 1024GB

NAND Flash: 3D TLC NAND Flash

Interface: SATA 3 (6Gb/s)

Sequential Read: UP to 550 MB/s

Sequential Write: UP to 510 MB/s

SATA SSD

128GB / 256GB / 512GB / 1024GB / 2048GB

NAND Flash: 3D TLC NAND Flash

Interface: SATA 3 (6Gb/s)

Sequential Read: UP to 550 MB/s

Sequential Write: UP to 510 MB/s

SATA SSD

128G / 256GB / 512GB / 1024GB / 2048GB

NAND Flash: 3D TLC NAND Flash

Interface: SATA 3 (6Gb/s)

Sequential Read: UP to 550 MB/s

Sequential Write: UP to 510 MB/s

__24C15hqqtC.png)

__24C15wOdCC.png)

__24C05XQ2my.jpg)

__24C05fplcZ.png)

__24C05vgHYC.png)